Products Center

Plates | RFID Tag Plates | RFID Plates | Custom RFID Plate Manufacturers | LASSORFID RFID Plates | RFID Catering Industry

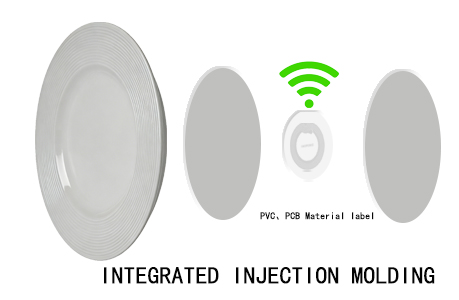

LASSORFID plates utilize an integrated injection molding process, combining RFID tags with food-grade materials to create tableware that meets food contact safety standards. These RFID smart plates meet IP68 protection standards, possessing waterproof, sh

LASSORFID plates utilize an integrated injection molding process, combining RFID tags with food-grade materials to create tableware that meets food contact safety standards. These RFID smart plates meet IP68 protection standards, possessing waterproof, shockproof, acid and alkali resistant, and tear-resistant properties. Thanks to the built-in RFID chip, each plate has a unique identification ID, providing physically uncopyable anti-counterfeiting features. By linking to a database of menu prices and information, this technology enables efficient data statistics and rapid pricing.

Currently, RFID smart plates on the market use different materials for chip encapsulation and the plate itself. The former protects the chip, while the latter forms the plate's main body, allowing the chip to be embedded without affecting its functionality. The main material systems are as follows:

1. Chip packaging materials

Epoxy resin: As a mainstream encapsulation material, it is widely used in the encapsulation of core tags on smart plates. This material effectively protects the chip, withstands operating environments such as plate washing and high-temperature sterilization, and has an applicable temperature range of -20~120℃, meeting the needs of catering scenarios. Its encapsulation structure allows for high compactness, facilitating embedding into the bottom of the plate.

Printed Circuit Board (PCB): RFID chips adapted to smart payment systems (such as the HT8185 tag) often adopt PCB substrate packaging, meaning the chip and antenna are integrated on the PCB substrate. This packaging method has excellent stability and long service life, ensuring high-reliability transmission of radio frequency signals. It is suitable for high-frequency use scenarios such as university canteens and chain fast food restaurants, and can withstand the mechanical wear and tear from repeated reading, writing, cleaning, and disinfection.

Polyvinyl chloride (PVC): A small number of RFID-enabled plates are encapsulated in PVC. This material is relatively inexpensive and easy to process, and can meet basic protection requirements. However, in catering applications, its high-temperature resistance and abrasion resistance are inferior to epoxy resin and PCB encapsulation materials, thus limiting its application range.

- Plate encapsulation material

Epoxy resin adhesive for secondary encapsulation: For plate materials such as ceramics where it is difficult to embed chips, transparent epoxy resin adhesive can be used to encapsulate and fix the surface-mount chip. This process firmly adheres the chip to the plate surface, and the epoxy resin layer combines transparency and aesthetics with waterproof sealing and protection against mechanical impact.

Plates | RFID Tag Plates | RFID Plates | LASSORFID RFID Plate Parameters

| Plate size | Customizable |

| Material | Melamine resin (MF) , epoxy resin adhesive , ceramics |

| Plate making process | Integrated injection molding |

| Protection level | IP68 |

| Label technical parameters | |

| RFID tag material | Epoxy resin , PVC, PCB |

| size | 40MM |

| Antenna manufacturing process | Copper Etching |

| Label sensitivity | Data read sensitivity less than or equal to -18dBm |

| Operating temperature | -40℃~85℃ |

| Storage temperature | -40℃~85℃ |

| Working in humid and hot conditions | 20%-93% (40°C) |

| Storage of humid heat | 20%-93% (40°C) |

| Operating frequency | 920-925MHz |

| Reading distance | ≥10cm static reading |

| Chip parameters | |

| Protocol Standard | ISO14443A, ISO15693 |

| Operating frequency band | 13.56MHz |

| Chip type | S50/FM1108/ult series/I-code series/N tag series |

| Storage capacity | 1k bits |

| Reading distance | ≥ 1 0 cm ( varies depending on reader type and reader antenna gain, etc. ) |